How it’s working

The machine is automatically or manually fed with bottoms or tops. The machine can fold pallets on two or three bottoms. Using the computer it is possible to program the so-called wings. After all the parameter settings have been made, the machine is ready for operation. The operator or robot places the bottoms and lids in the designated areas. The machine itself takes the elements, positions them, and then carefully picks up the pallets. The machine has its own hydraulic unit (also sufficient for connection with other machines, eg a pallet stacker, a robot).

Product information:

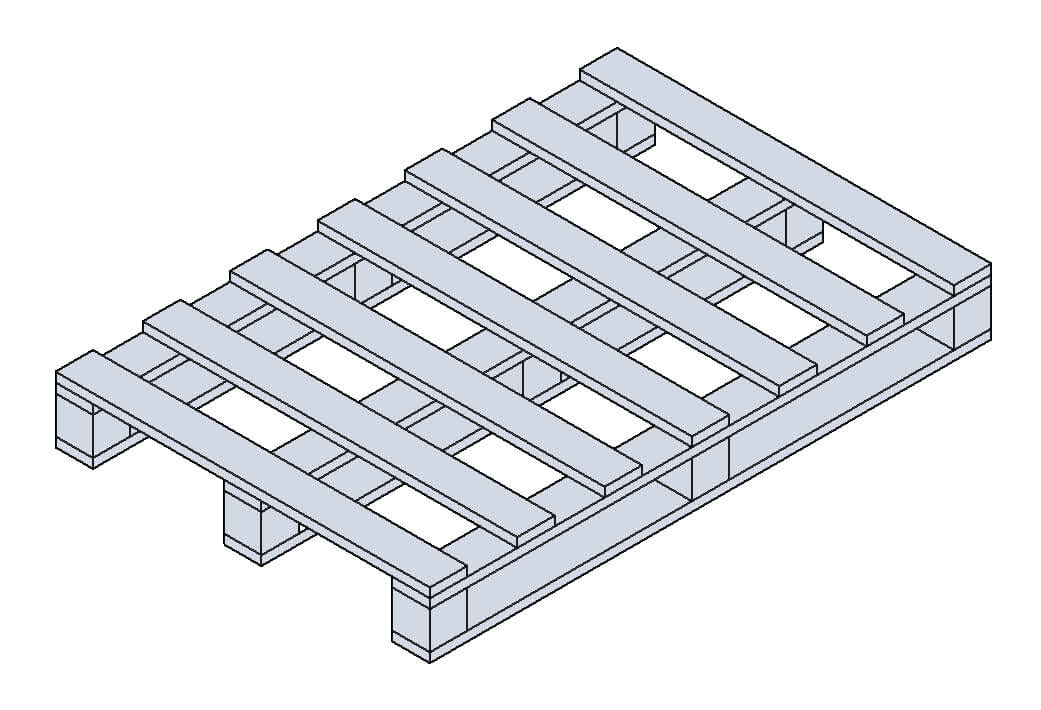

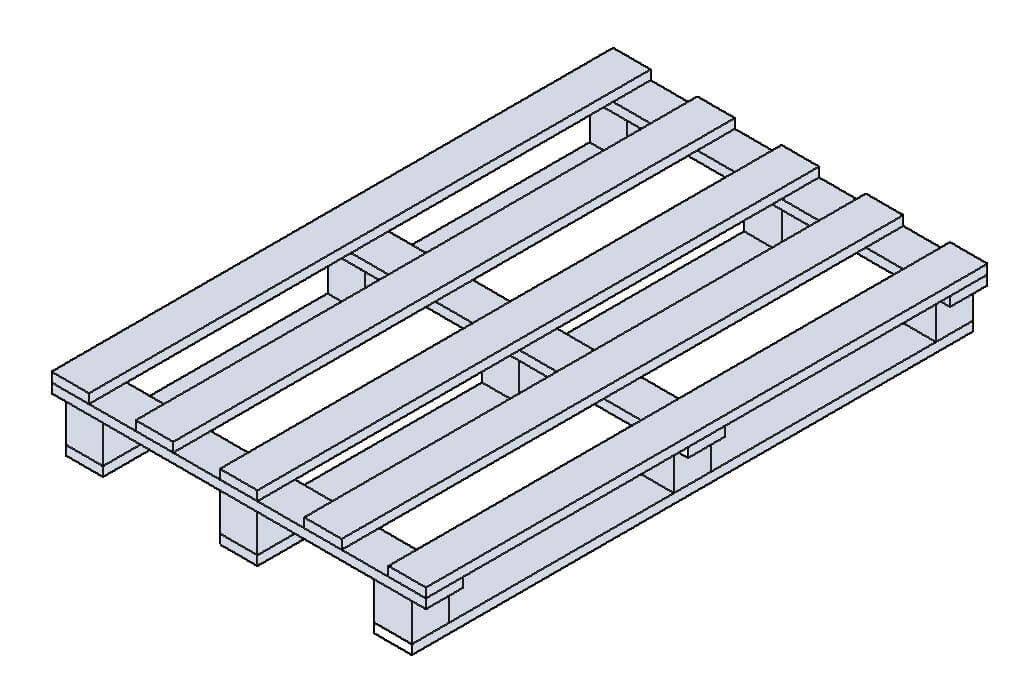

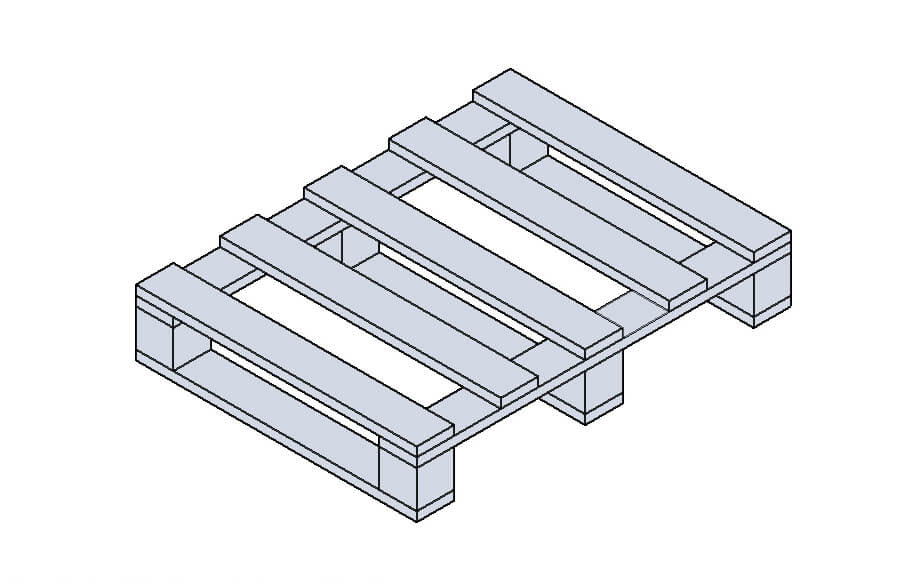

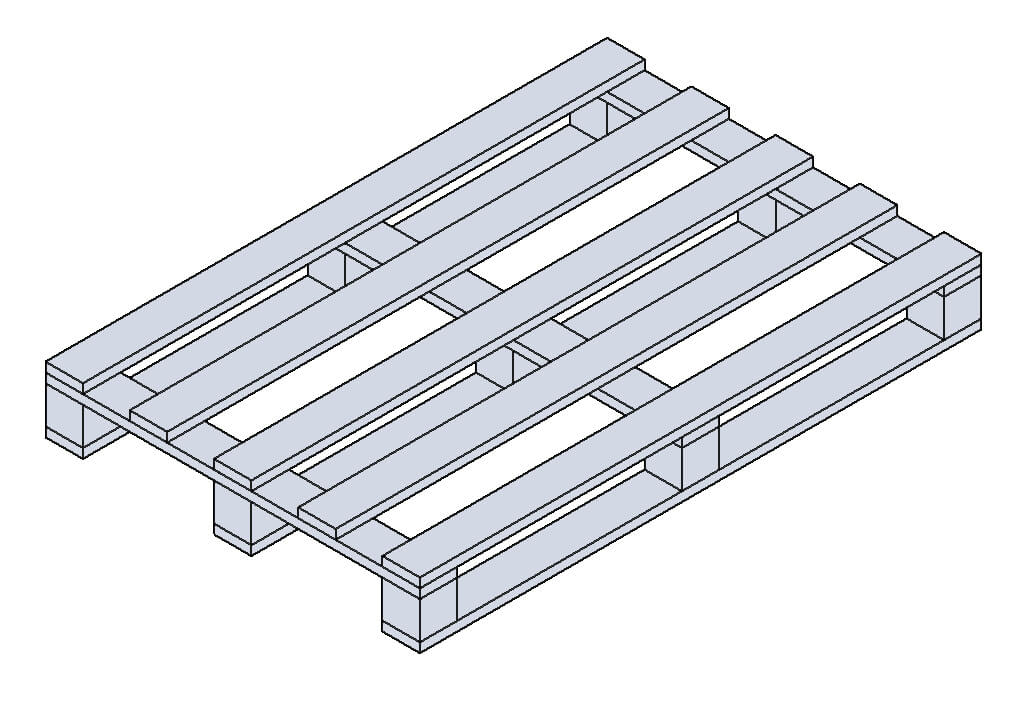

The machine is used to connect a finite table top with bottoms. The pallets can be combined with the so-called with or without wings. Using the electronic quick set-up system, the machine is ideally suited to the production of even small pallet series.

Attributes

- piling pallets on 2 or 3 bottoms,

- completely automated way of feeding elements,

- the use of Pulse Counter technology, accurately positioning the palette,

- programmable number of nails nailed,

- an innovative nailing system,

- control of nails,

- service: 1 operator or robot,

- fast and precise dimensional change system,

- possibility of single work or in a production line,

- has its own control panel and hydraulic unit.

The most important features:

5 pallets per minute

One operator

Quick change of dimensions

Control panel

Control of nails embedded

Material dimensions:

Caps:

- Thickness: 24-64 mm

- Width: 600-1500 mm

- Length: 600-1400 mm

Bottoms:

- Height: 87-132 mm

- Width: 75-145 mm

- Length: 600-1500 mm

Dimensions of nails:

- Thickness: 3.1-3.5 mm

- Quality: machine nails

- Length: 50-100 mm

Finished palettes:

- Height: 111-196 mm

- Width: 600-1500 mm

- Length: 600-1400 mm

Efficiency:

- 4 4-entry pallets / min, when the pallet length is up to 1400 mm, and the bottoms have 3 blocks.

- 3.5 4 pallets / minute, when the pallet length is a maximum of 2500 mm, and the bottoms have 5 blocks.

- Adjustment time 5-10 min.

- Maximum load: 200 kg on the platform

Technical requirements:

- Electrical voltage: 3-phase 400 V, 50 Hz

- Main fuses: 3×63 Amper

- System pressure: 6-10 bar

- Nominal pressure: 6-7 bar

Dimensions of the machine:

- External dimensions of the machine: See line diagram.

- Recommended hall height: 4400mm, recommended height to keep about 2m free space above the machine.

Other:

- Dimensions of the wings: normally, 0-100 mm, along the transverse board.

- For wings other than normal, please contact IMH for individual matching.

The machine does not meet all your expectations?

Contact us: info@maszynydopalet.pl, and thanks to cooperation with the machine manufacturer IMH Machinery AB, We will create a product tailored to your needs.